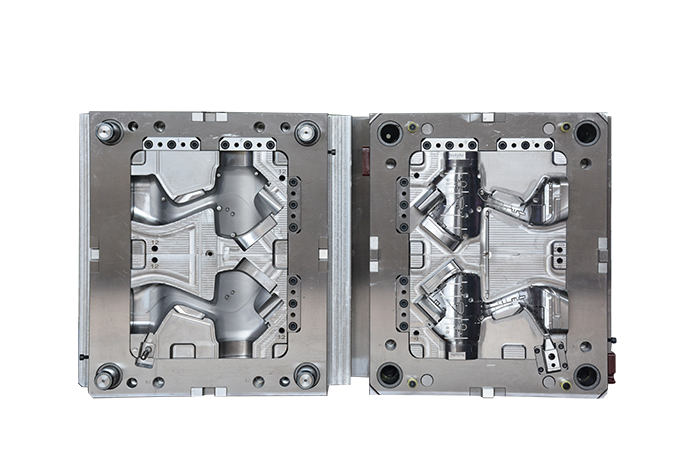

In the design of injection mold parts, the number and arrangement of mold cavities should be designed first. Mold cavity design can not simply apply the dimensional tolerance of mechanical parts, the dimensional accuracy of plastic parts will be affected by many factors such as the structure of plastic parts, plastic materials and the shrinkage rate of plastic parts in production. Therefore, the arrangement of injection mold cavity should follow certain principles to meet the requirements of mold manufacturing.

顺之盈注塑模具型腔的排位大致要求如下:

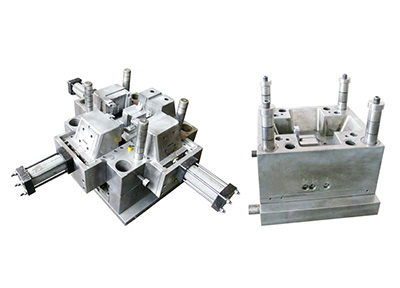

1.流道尽可能短:防止浇注系统凝料,还可以节约钢料及模具制造成本,提高注塑产品的合格率。

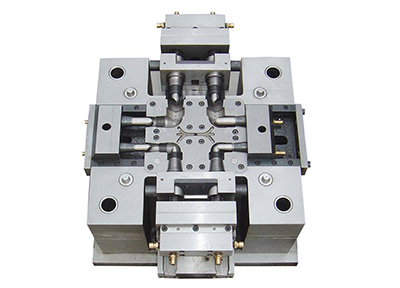

2.压力平衡:使注塑模具在注射时承受的合力与注塑机的锁模力在同一条直线上,避免不平衡的流动导致分子取向不规则,引起收缩率不一致。

3.温度均衡:使注塑模具型腔各处的温度大致相等,保证各型腔塑件的收缩率相等。

4.进料均衡:对于一模多腔的模具,同一塑件应从同一位置进料,以保证塑件的互换性;流道和浇口的大小、长短应与塑件大小相适应,尽量保证各型腔同时进料,同时均匀填充各个型腔。

合理设计注塑模具成型零件,保证塑件的成型质量,是提高注塑模具的生产效率的基本原则。

- 2007-08-27

Shunzhiying Mould participated in the A… - 2018-12-07

Our company has added new projects - 2018-12-07

What are the requirements for the desig… - 2018-08-08

What process can be used to change the … - 2018-12-07

Application of plastic injection mold i… - 2017-12-07

PEEK Injection Molding - 2019-06-06

What are the injection molding conditio…

管理员

该内容暂无评论