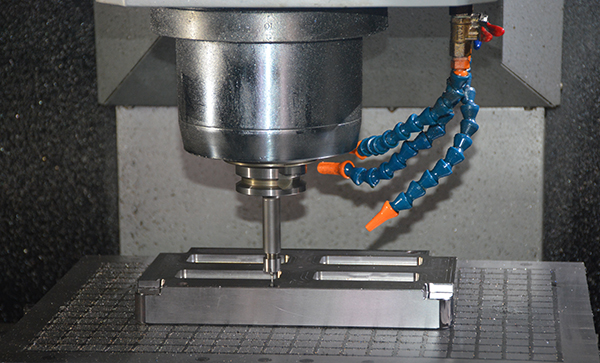

One of the common problems in CNC milling is the surface finish. There are many reasons for the poor or change of the surface quality of the workpiece processed by the mould

The first reason is that the tool is too blunt. A blunt knife will deform the workpiece more. This will increase the cutting force, and with the accumulation of deformation, the cutting edge will go deeper into the part, and if the chip breaks suddenly, it will leave a small hole. This will greatly reduce the surface finish of the mold parts.

Another reason is CNC milling strategy. There are two milling strategies: climbing and conventional. The first strategy is that the tool rotation direction is consistent with the table feed direction. When climbing milling is used, the tool will be impacted into the workpiece, and then slowly exit the workpiece with the least material (the surface created after machining). This produces a good surface finish. When the number of revolutions is opposite to the feed direction, conventional milling is performed. In this way, the tool enters the workpiece from the finished surface. Due to slight vibration and process changes, the tool may slightly damage the surface of the finished part. However, this is enough to change the final surface finish

The last reason for the poor surface finish of die parts is the improper selection or lack of coolant. Many people underestimate the role of coolant and lubricants. In fact, the use of proper coolant lubricants can improve the quality of the entire surface.

resolvent:

In order to make the surface finish of die machined parts as high as possible, you should maintain the cutting tools, use the correct strategy and pay attention to the selection of the appropriate coolant.

Surface burn of common workpiece defects in CNC milling.

Surface burn refers to the surface burn along the machined parts. Burn means that the workpiece is overheated.

The causes are as follows:

The wrong cutting parameters will lead to the defects of the workpiece processed by the die. Improper selection of feed and speed may seriously damage the workpiece, cutting tool and even the machine itself.

terms of settlement:

One way to solve this problem is to reduce the cutting speed and feed ratio. It makes the process slow down and the temperature decreases.

Another method is to increase the cooling rate in the process. In some extreme cases, such as titanium with poor thermal conductivity, both methods are necessary.

- 2007-08-27

Shunzhiying Mould participated in the A… - 2018-12-07

Our company has added new projects - 2018-12-07

What are the requirements for the desig… - 2018-08-08

What process can be used to change the … - 2018-12-07

Application of plastic injection mold i… - 2017-12-07

PEEK Injection Molding - 2019-06-06

What are the injection molding conditio…

管理员

该内容暂无评论